There is no doubt that the best solution

for the manipulation of steel industry products

is electromagnetism.

Lifting Electromagnets

It has been demonstrated that of all the options available, Electromagnetic Lifting Equipment is increasingly the undisputed first choice.

In order to achieve the kind of boost to productivity demanded by an ever more competitive market, it’s a good idea to start by rationalising product movement and optimising available space.

Magnetic equipment is used to handle all kinds of iron and steel products automatically, reducing the storage space needed and consequently cutting transfer distances to bring a final time saving that makes a big difference.

FYLSA carries out a personalised study into each individual case.

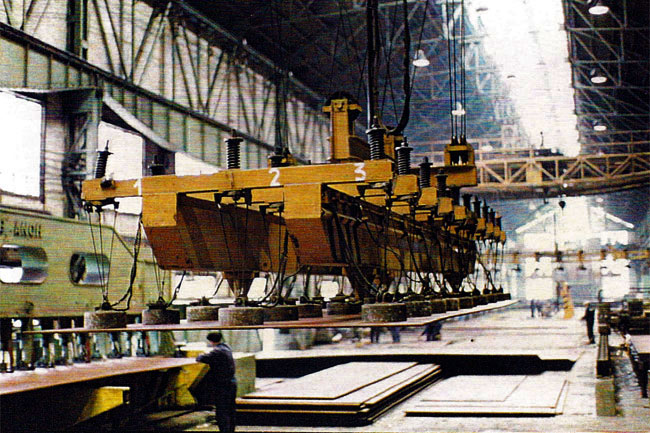

Billets, Slabs and Plates

FYLSA electromagnets allow high-temperature parts like billets to be handled quickly and safely.

In this area, FYLSA offers a robust and resistant design that will stand up to the toughest conditions, with the capacity to work at temperatures of up to 650ºC.

FYLSA offers a individualised study into the specific needs of each customer, looking at both the volume of billets to be lifted and the geometric and thermal conditions where lifting takes place.

Corrugated Metals, Profiles and Pipes

Chains, slings ... they just became unnecessary.

Electromagnetic equipment offers safe handling of all kinds of ferromagnetic product, regardless of their weight or geometry.

FYLSA designs equipment with electromagnets suspended from articulated beams that allow us to do everything from rotating the electromagnets to modifying the distance between apparatus using telescopic beams.

By combining these systems, one set of equipment is able to cover a wide range of needs.

Rolls of Corrugated

Over the last few years, FYLSA has developed a toroidal geometry electromagnet that can adapt to all the geometries presented by the different coils of corrugated steel / construction rods currently available from different rolling mills.

The design of the different coils allows us to ship them either as single units or in batches.

Handle Scrap

With their robust design, FYLSA electromagnets for scrap are ready to receive the kinds of impact associated with this sort of work.

Its lightweight aluminium coil is insulated to enable it to absorb impacts and then housed in a cast steel casing of high mechanical resistance.

The use of the initial impulse system enhances the capacity in the electromagnet by up to 25%.

For applications in moving vehicles, detailed studies are undertaken according to machine type.

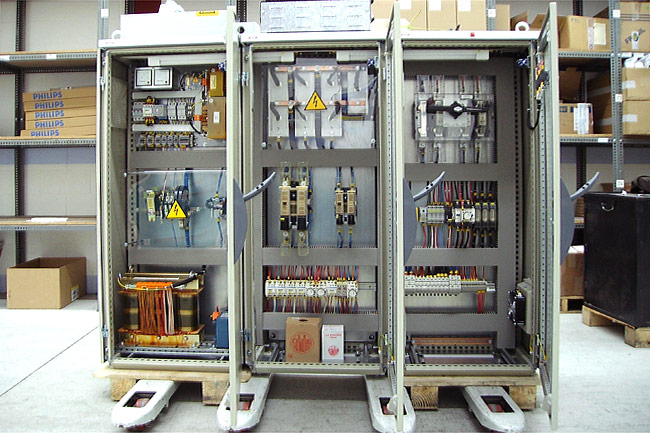

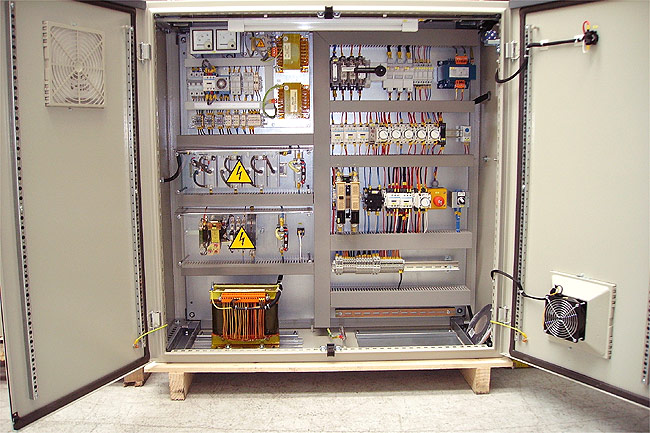

Electrical Magnetisation Equipment

In response to the latest market demand, FYLSA now offers its customers robust and reliable electrical magnetisation equipment designed to stand up to the toughest working conditions.

Starting with equipment that is straightforward in concept and easy to maintain, FYLSA makes all of its products highly versatile and capable of adapting to any kind of facility.

This versatility allows us to include safety systems, electromagnet selection, initial impulse manoeuvre, electromagnet status control, battery status control and other advantages. These are developed using PLCs, touch screens integrated into the equipment, incident identification systems, manoeuvre counters and status registers which together provide total control over conditions in the facility.

All of this is intended to minimise risks, maintenance costs and inspection intervals, always putting the needs of our customers foremost.

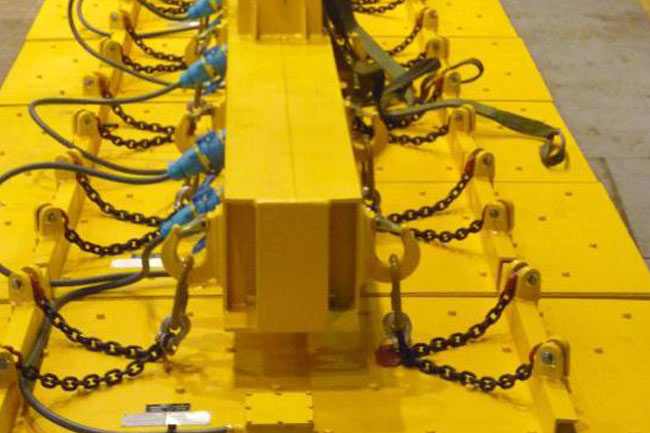

Suspension Beams

Due to the wide variety of products available on the iron and steel market, FYLSA offers a range of solutions for the suspension of our electromagnets.

We always seek to find the best solution, taking into account the individual aspects of each customer’s needs and facilities.

Our manufacturing range covers everything from welded-structure fixed beams to mechanisms with varying degrees of independence (expandables, electromagnetic rotation, alignment and misalignment of electromagnets etc.).

When designing and developing these actions, we consider different types of solution, which could be hydraulic, electromechanical, pneumatic, etc., depending on which best meets the needs of the end user.